// Softwarepaketierung

Leistungsstarke Lösungen für die klassische, moderne und zukunftsorientierte Softwarepaketierung.

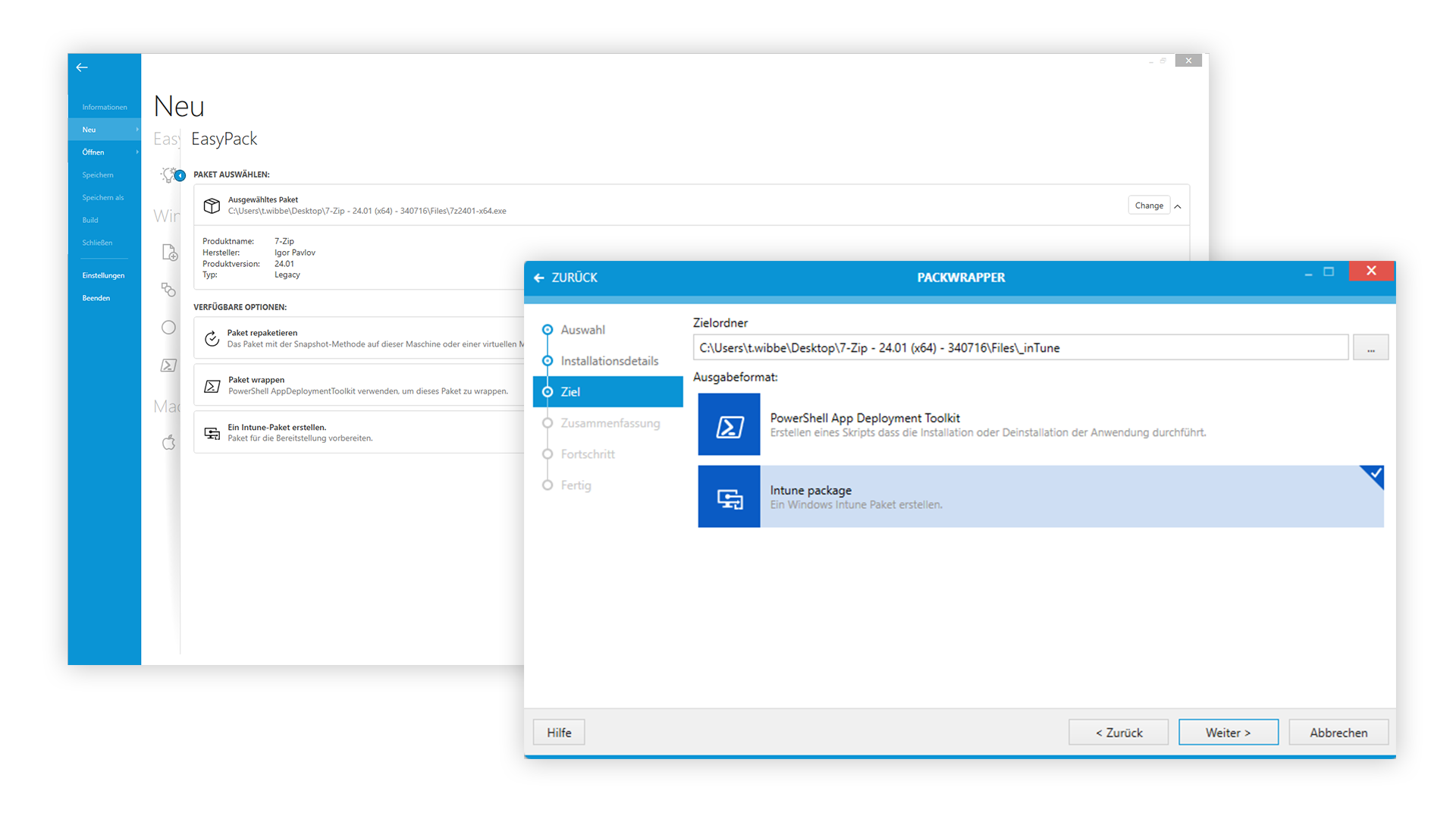

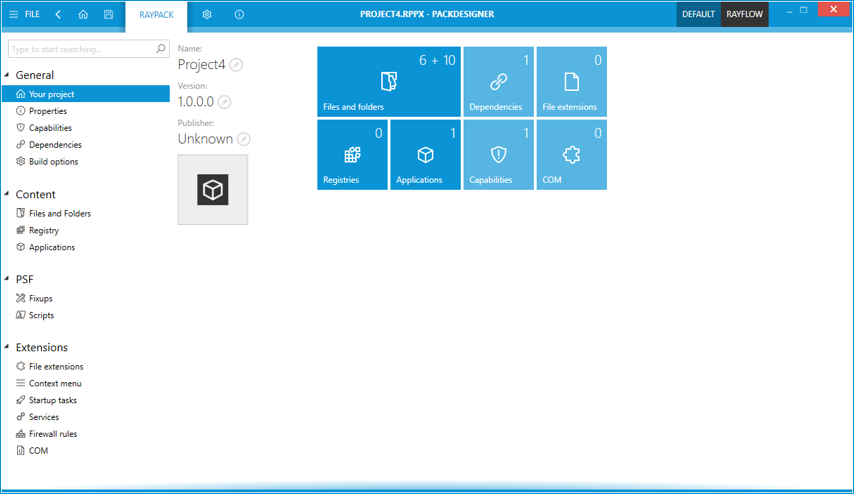

// RayPack Studio

Beschleunigen Sie komplexe Paketierungsprozesse & Routine-Aufgaben

RayPack Studio ist der Gamechanger für eine ganzheitliche und effiziente Softwarebereitstellung und deckt dabei sämtliche Arbeitsschritte in einer einzigen Gesamtlösung ab.

- Automatisierte Erstellung von professionellen Paketierungsanleitungen

- Kontinuierliche Sicherstellung der Qualität von Softwarepaketen

- Mühelose & KI-gestützte Erstellung von komplexen Softwarepaketen

- Sofortige Ergebnisse für mögliche Störfaktoren während einzelner Arbeitschritte

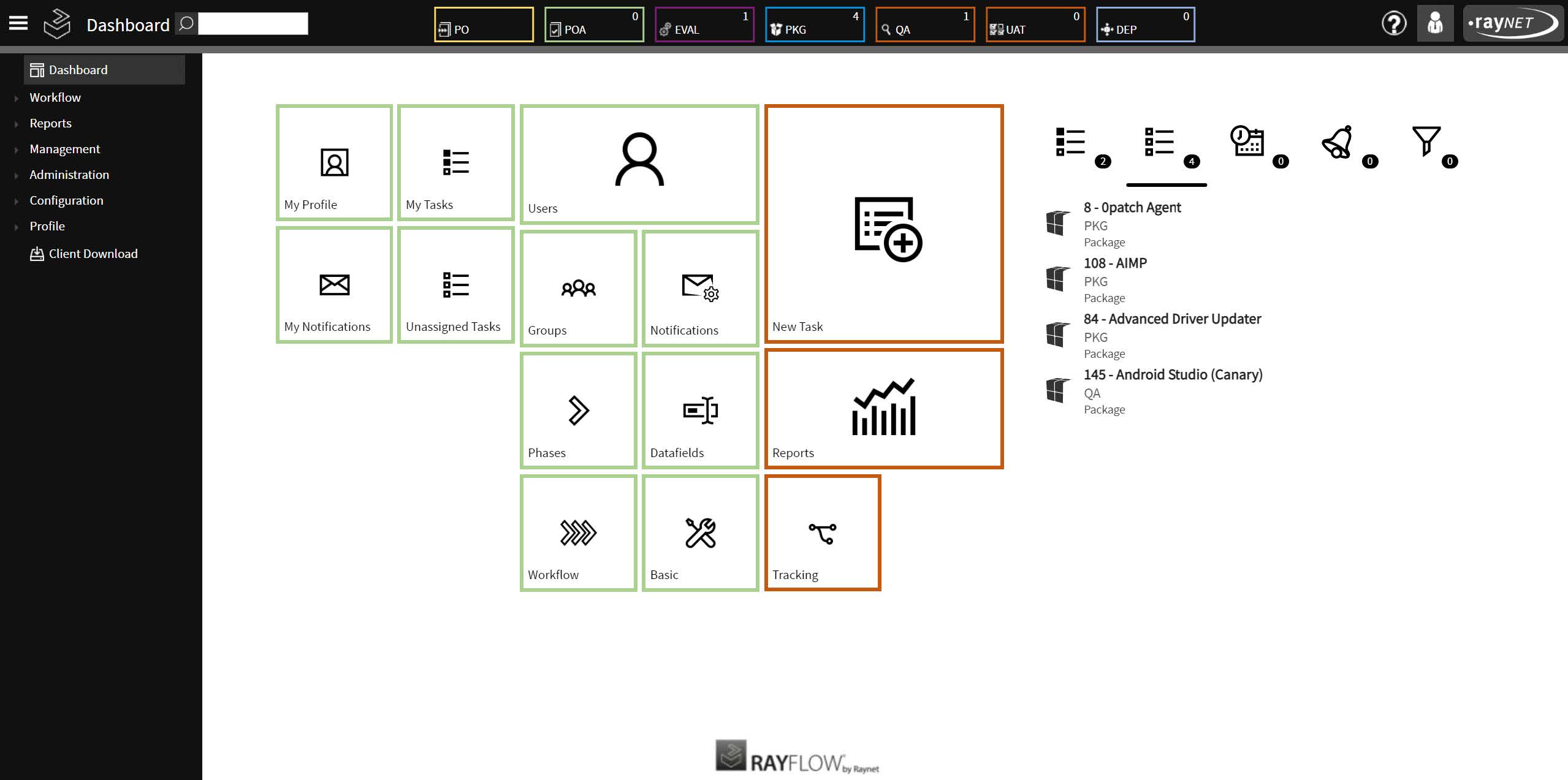

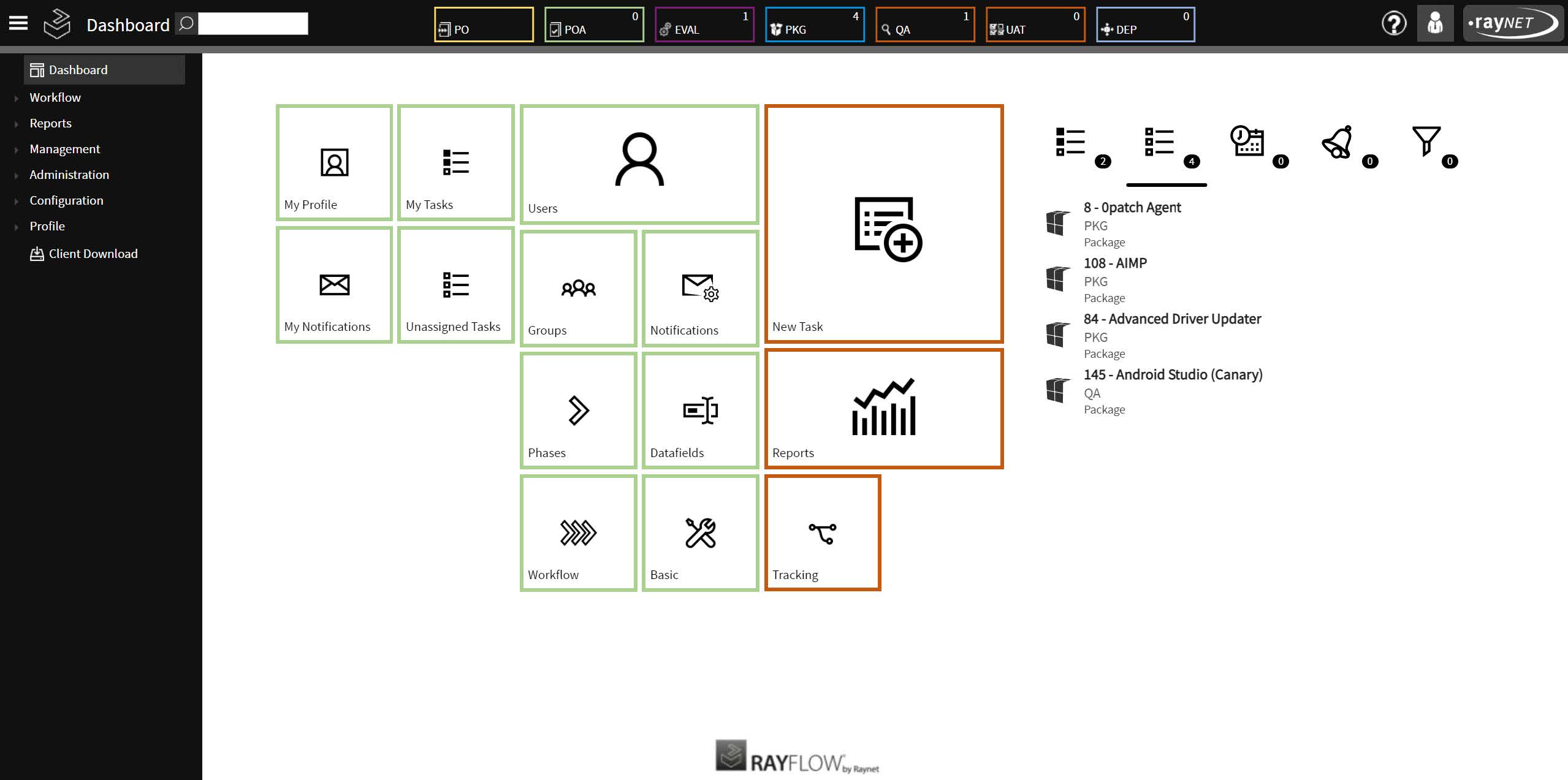

// RayFlow

Verwalten Sie unternehmensweite Workflow-Prozesse effizient & flexibel

RayFlow ist eine intelligente Workflow Management-Lösung, die sämtliche, wichtige Informationen innerhalb des Application Lifecycle-Auftrages sammelt und für verschiedenste Teams transparent darstellt.

- Beschleunigung von Paketierungsprozessen und Software-Roll-Outs

- Hohes Maß an Transparenz durch Echtzeit-Tracking

- Intuitive Bedienung und unkompliziertes Onboarding

- Reduzierung von Softwarekosten und Softwarefehlern

- Schnittstelle für Teams und Standorte für diverse Berichte und Updates

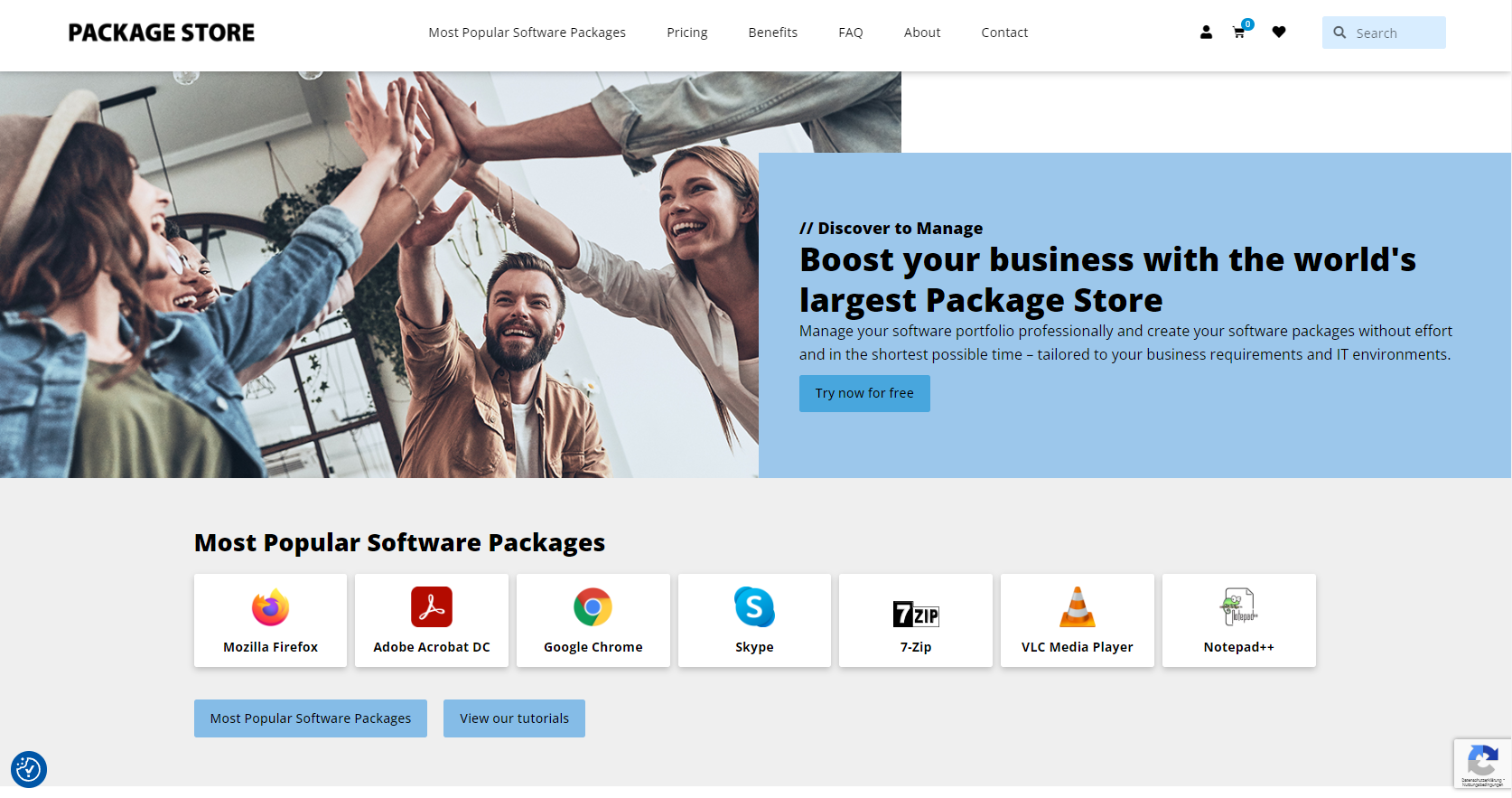

// Package Store

Sparen Sie wertvolle Zeit durch sofort einsatzbereite Softwarepakete

Der Raynet Package Store verfügt über die weltweit größte Bibliothek an vorkonfigurierten Softwarepaketen für die Ad-hoc-Bereitstellung von Updates oder Patches, sowie als Quelle für komplexe und individuelle Paketierungsaufgaben.

- 93 % Zeitersparnis durch qualitätsgesicherte Softwarepakete

- Vollständiger Return on Investment innerhalb von nur einem Monat

- Direktes Publishen von Softwarepaketen in Microsoft Intune

- 24/7 Zugriff auf über 80.000 Softwarepakete für Windows & macOS

- Von der Auswahl bis zum verteilfähigen Paket in nur 2 Minuten

// We are, where you are

Kontaktieren Sie unsere Experten

Sie interessieren sich für unsere Lösungen, benötigen weitere Informationen oder haben Fragen?

Mit fast 25 Jahren Erfahrung und zahlreichen Kundenprojekten weltweit, können wir auch Ihnen bei Ihren Herausforderungen helfen – kontaktieren Sie uns noch heute!

// Softwarepaketierung

Leistungsstarke Lösungen für die klassische, moderne & zukunftsorientierte Softwarepaketierung.

// RayPack Studio

Beschleunigen Sie komplexe Paketierungsprozesse & Routine-Aufgaben

RayPack Studio ist der Gamechanger für eine ganzheitliche und effiziente Softwarebereitstellung und deckt dabei sämtliche Arbeitsschritte in einer einzigen Gesamtlösung ab.

- Automatisierte Erstellung von professionellen Paketierungsanleitungen

- Kontinuierliche Sicherstellung der Qualität von Softwarepaketen

- Mühelose & KI-gestützte Erstellung von komplexen Softwarepaketen

- Sofortige Ergebnisse für mögliche Störfaktoren während einzelner Arbeitschritte

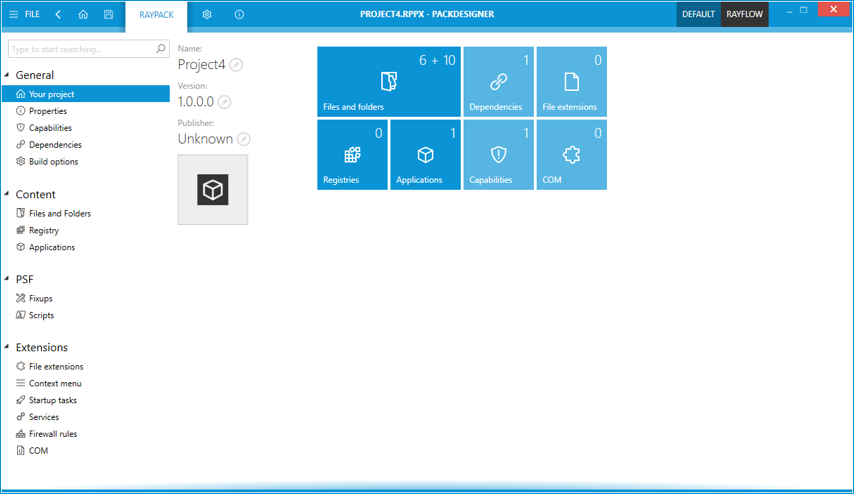

// RayFlow

Verwalten Sie unternehmensweite Workflow-Prozesse effizient & flexibel

RayFlow ist eine intelligente Workflow Management-Lösung, die sämtliche, wichtige Informationen innerhalb des Application Lifecycle-Auftrages sammelt und für verschiedenste Teams transparent darstellt.

- Beschleunigung von Paketierungsprozessen und Software-Roll-Outs

- Hohes Maß an Transparenz durch Echtzeit-Tracking

- Intuitive Bedienung und unkompliziertes Onboarding

- Reduzierung von Softwarekosten und Softwarefehlern

- Schnittstelle für Teams und Standorte für diverse Berichte und Updates

// Package Store

Sparen Sie wertvolle Zeit durch sofort einsatzbereite Softwarepakete

Der Raynet Package Store verfügt über die weltweit größte Bibliothek an vorkonfigurierten Softwarepaketen für die Ad-hoc-Bereitstellung von Updates oder Patches, sowie als Quelle für komplexe und individuelle Paketierungsaufgaben.

- 93 % Zeitersparnis durch qualitätsgesicherte Softwarepakete

- Vollständiger Return on Investment innerhalb von nur einem Monat

- Direktes Publishen von Softwarepaketen in Microsoft Intune

- 24/7 Zugriff auf über 80.000 Softwarepakete für Windows & macOS

- Von der Auswahl bis zum verteilfähigen Paket in nur 2 Minuten

// We are, where you are

Kontaktieren Sie unsere Experten

Sie interessieren sich für unsere Lösungen, benötigen weitere Informationen oder haben Fragen?

Mit fast 25 Jahren Erfahrung und zahlreichen Kundenprojekten weltweit, können wir auch Ihnen bei Ihren Herausforderungen helfen – kontaktieren Sie uns noch heute!